Custom Connected Technology

Connected Worker uses hardware and software technologies to support frontline heroes in the field.

The technologies include a combination of:

-

Wearables

Wearables

-

Desktop Computer/Laptop/ Tablet/Phone

Desktop Computer/Laptop/ Tablet/Phone

-

Camera

Camera -

Software that varies according to need

Software that varies according to need

-

Connectivity

Connectivity -

Database/Resource Center

Database/Resource Center

-

Mic and Speaker with noise- cancellation functionality for loud environments

Mic and Speaker with noise- cancellation functionality for loud environments

Frontline heroes and their supporters behind the scenes benefit from two-way audio, video communication, and conferencing technology.

The solution is optimized for wearable devices (which can be mounted on multiple types of headgear) but can also be enabled on smartphones and tablets:

Navigator 520 with Standard Camera and Hard Hat

Navigator 520 with Thermal Camera and Workband

Workband

Tablet

Phone

When used with Collaborate V2 or paired with software, the wearable device can be used to display and share the worker’s viewpoint on many devices, such as:

.png)

CBT has the know-how to architect a solution that meets the unique needs of heroes in any industry.

See how Connected Worker technology has been used by frontline heroes in key industries to increase productivity, promote safety, and boost profits.

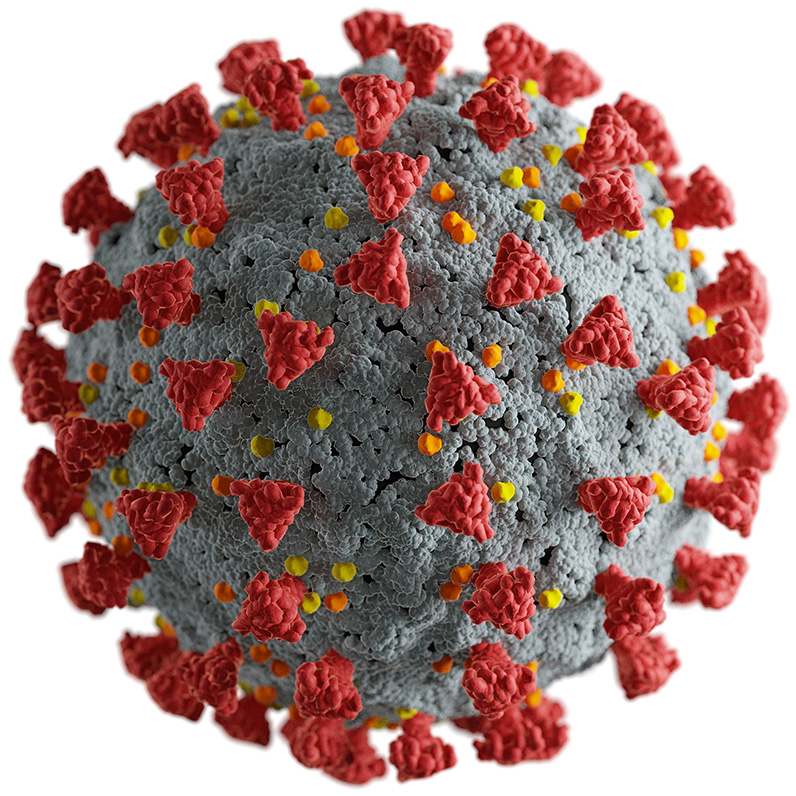

Healthcare

Healthcare heroes can consult with each other during procedures and while examining patients. Connected Worker technology can be used in telemedicine to:

Train employees and transfer hands-on knowledge

Examine patients remotely

Receive real-time advice from specialists

Flatten the learning curve for students/residents

Complete documentation via voice command

Collaborate remotely using 1-on-1 and conferencing functionalities

Experts from all over the world could collaborate and contribute to a critical procedure

Expedite care

Decrease the use of PPE

Perform hands-free thermal imaging to detect patient temperature

Reduce the chance of infection

Every year, 2 million patients suffer from infections in the U.S.1

Decrease the infection rate of healthcare heroes by reducing the number of on-site workers needed for examinations, diagnoses, and care

Hospital infections result in 90,000 deaths each year.1

Reduce the chance of infection

5-10% of patients contract infections while receiving care in hospital environments.1

Oil & Gas

Texmark Chemicals used Connected Worker to achieve the Refinery of the Future.2 The petroleum product manufacturer found multiple IoT use cases for the technology.

The frontline heroes in the oil and gas industry who fuel our communities can use Connected Worker to:

Increase safety

Equipment is certified for use in C1D1 environments

Frees utility workers’ hands and limits distractions

Reduce the maintenance equipment workers need to carry

Manage asset integrity

Drive maintenance efficiency

Receive IoT sensor readings

See historical trend data

Decrease the use of PPE

Instantly gain virtual access to critical info, such as schematics, P&IDs, maintenance logs, manuals, etc.

View real-time asset readings and customizable data dashboards through the wearable

Boost profitability via efficiency

Bolster compliance procedures by

Taking photos and video via voice command

Gaining digital access via the wearable to meet compliance regulations/standards documentation

Using voice commands to fill out forms in the field and document completed work with timestamped, geo-located photos/videos

Increase training capabilities

On-the-job training from remote experts anywhere in the world

Incorporate process workflows and training videos to ensure high-quality work from any employee, regardless of experience level

Decrease time to respond in critical situations

Simply connect on-site employees to SMEs virtually so they can see through the on-site employee's eyes

Decrease time to respond in critical situations

Connect multiple experts to field rep for one-to-many conferencing advice

Decrease time to respond in critical situations

No need to fly in an expert resource

Utilities

Utility companies that supply vital water and power can use Connected Worker to support their frontline heroes as they install and service equipment in the field by allowing them to:

Receive IoT sensor readings

See historical trend data

Decrease the use of PPE

Instantly see manuals/ schematics

Connect to remote experts

Communicate with the command center and expert resources through:

On-the-job training from remote experts anywhere in the world

Live annotation

Conferencing

Connected technology also keeps utility heroes safe by freeing their hands and limiting distractions. Connected Worker also replaces traditional paper and pen records.

Heroic utility workers can:

Conduct employee training and knowledge transfer

Heroic utility workers can:

Access standards and compliance information

Heroic utility workers can:

Enter data into spreadsheets and forms

Heroic utility workers can:

Retrieve and enter data needed for documentation without using their hands

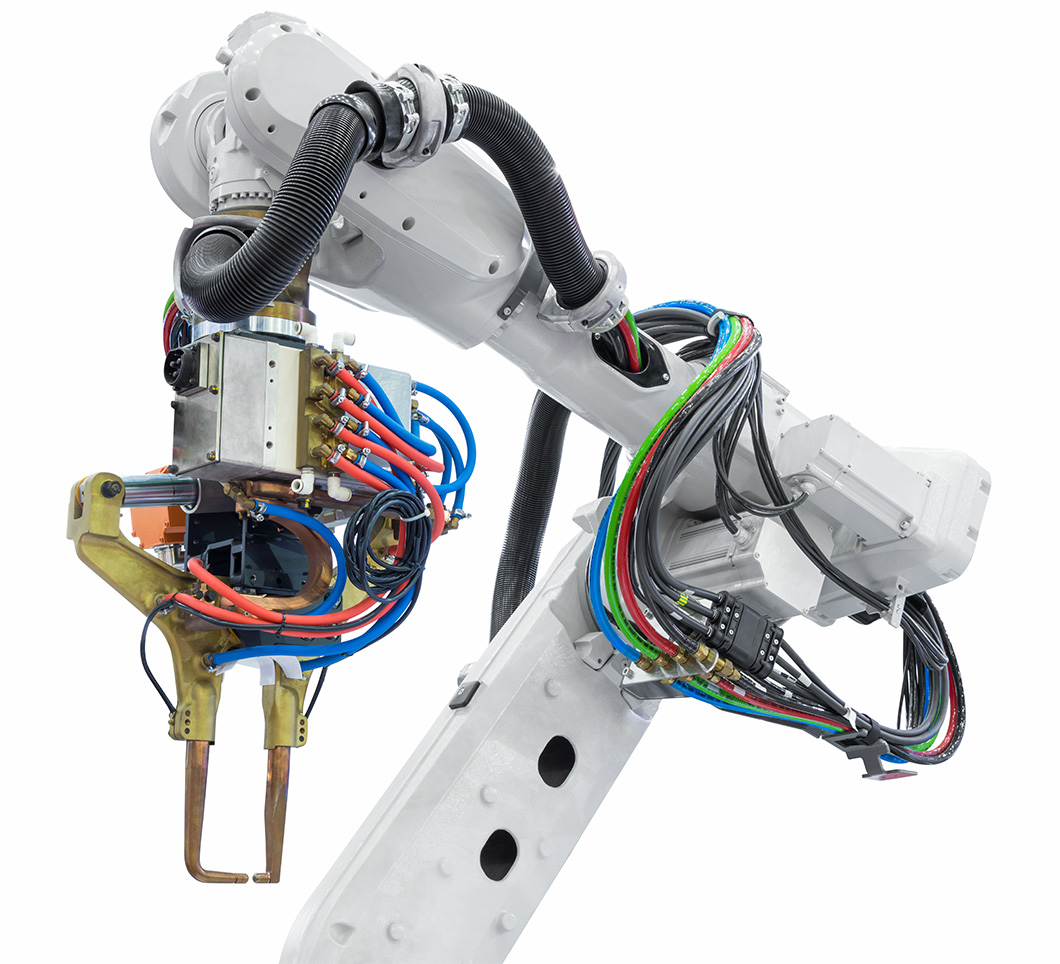

Manufacturing

Industry Week reported that technologies that guide people who set up and operate equipment are instrumental.3 Connected Worker helps the heroes at the manufacturing companies we rely on for essential products:

Receive IoT sensor readings

Maintain quality control and standards

Connect with remote experts for quicker repairs and maintenance

Conduct audits

Promote safety

Improve and expedite maintenance procedures

Reduce factory downtime which directly impacts the bottom line

Reduce factory downtime which directly impacts the bottom line

Construction

Brave construction workers are exposed to necessary risk as they complete crucial infrastructure projects. Connected Worker helps these heroes:

Operate cranes:No more “blind lifts” or relying on hand signals

Manage projects in the field

Train employees and transfer knowledge

Increase safety by freeing workers’ hands

In 2018, there were non-fatal injuries to 3 out of every 100 construction workers.4

With connected technology, construction workers stay in communication so they can get help quickly after an accident.4

Automotive

Automotive worker heroes keep the U.S. productive and ensure our vehicles run safely. Connected Worker supports the automotive industry by helping with:

Training service workers

Training service technicians

Decreasing time needed for repairs

Inspecting products for nonconformities

Providing technicians with remote expert resources

Safety

Letting customers see what the technician sees

Envision How Connected Worker Can Support Your Frontline Heroes

The use cases for Connected Worker are endless.

At CBT, we work with our customers to find appropriate use cases and customize the solution to meet their needs. We collaborate closely with organizations and their workers to innovate ways for using Connected Worker.

Once you see the technology in action, you’ll envision how it will transform your business.

Seeing is believing. Receive a virtual demo from a CBT expert and see for yourself what Connected Worker can do.

SOURCES

- CB Technologies | https://www.cbtechinc.com/connected-worker-healthcare-solutions

- CB Technologies | https://www.cbtechinc.com/connected-worker-and-iiot-refinery-of-the-future

- Industry Week | https://www.industryweek.com/technology-and-iiot/article/21129510/technology-takes-center-stage-as-manufacturers-pivot

- Bureau of Labor Statistics | https://www.bls.gov/web/osh/summ1_00.htm#soii_as_t1.f.1