Asset Integrity Management

Reduce Risk & Expedite Decisions

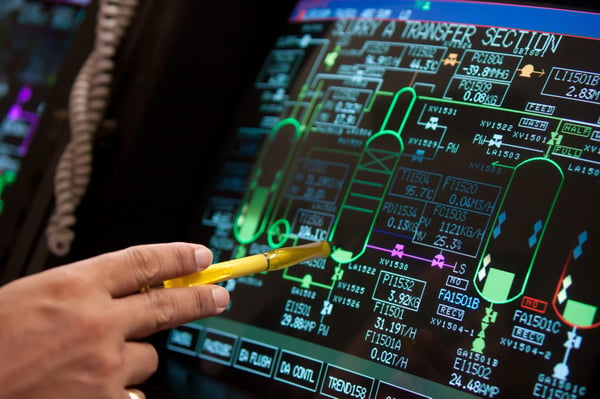

Asset Integrity Management provides expedited access to asset maintenance, performance & location/ tracking information, allowing for optimized inspection and repair activities, and planning of new workloads. With immediate access to relevant asset information such as P&IDs, specification tolerances, maintenance logs, instruction manuals and more, workers can make more informed decisions faster, with significantly less time wasted searching for information.

Our Asset Integrity Software streamlines data retrieval for the control center and workers in the field. You can retrieve documents digitally (manuals, asset drawings, inspection reports, etc.) , see a 3D rotational view of assets and obtain risk-based inspection graphs – all at the click of a button.

CBT’s Asset Integrity Management solutions are offered in partnership with Antea and Hewlett Packard Enterprise.

Use Cases

Inspection & Quality Control

Emergency Response

Predictive Maintenance

Preventative Maintenance

Risk Analysis

Industries

Asset Integrity Management has real-world applications across a multitude of industries. It is especially relevant in asset-intensive verticals such as Oil & Gas, Energy, Utilities and Manufacturing, expediting decision making by providing real-time access to critical data.

How We Do It

Innovation Delivery as a Service (IDAAS) is CBT’s proven process that de-risks innovation and gives you the best chance for digital transformation success. Delivering real results through constant evolution, transformation, rapid iteration, innovation, and support.